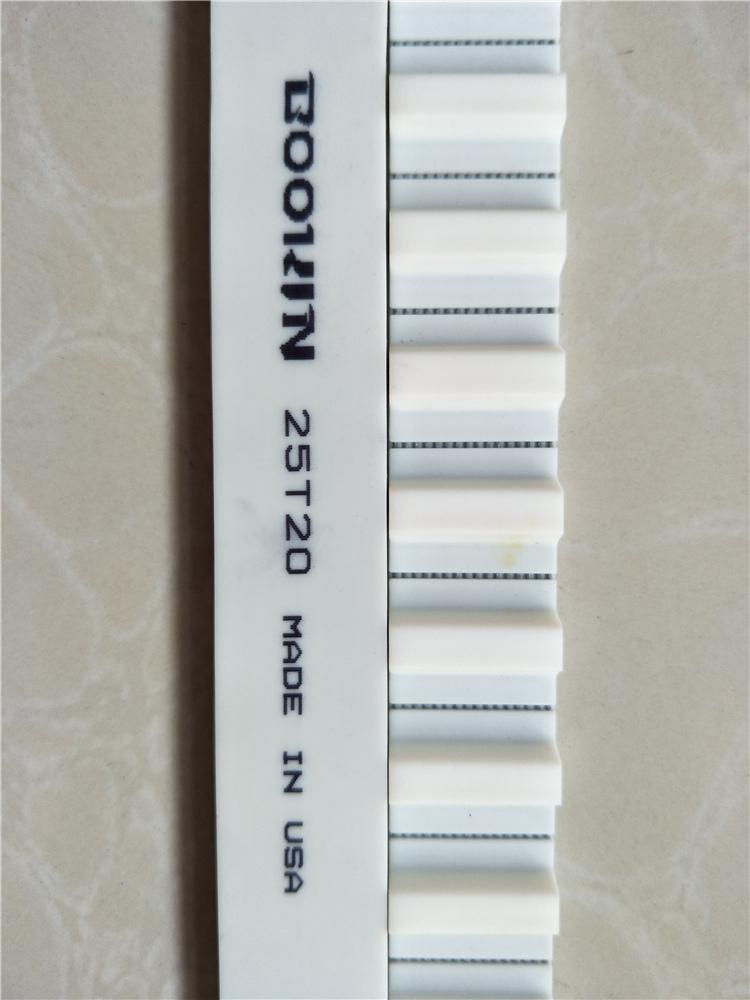

聚氨酯同步带美国进口BOOKIN博金公制梯形齿T20数据表

BOOKIN博金美国进口聚氨酯同步带公制梯形齿T20数据表T20聚氨酯同步带传动特性▪带有钢制带芯的聚氨酯同步带▪符号DIN7721T1标准的梯形齿形▪公制节距20mm▪非常适合高柔性传动的应用▪广泛用于输送、线性传动和轻载动力传输应用▪可提供双面带齿的产品▪宽度公差:±1.0[mm]▪长度公差:±0.5[mm/m]▪厚度公差:±0.4[mm]技术参数带宽b[mm]允许拉伸载荷M型FTzul[N]允许拉伸载荷V型FTzul[N]断裂载荷M型FBr[N]弹性刚度比Cspez[N]重量[kg/m]25166.883.4646417000.1832168.484.2653.142109.40.2450171.685.8665429000.3775173.286.6671.3433000.55100174087674.5435000.73150169.884.9658.642466.61,10根据要求可提供其他宽度。T20聚氨酯同步带齿剪切强度rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]0104,5080062.15190046.88450030.9220101,1090060.13200045.94500028.934098.15100058.31220044,20550027.146095.58110056.64240042.61600025.498093.35120055.11260041.13650023.9710091.41130053,70280039.7720083,50140052.38300038.4930077.84144051.87320037.2940073.49150051.14340036.1650069.96160049.98360035,1060066.98170048.89380034.0970064.41180047.86400033.13载荷率Fuspez是指在各种工作条件下1cm宽的单个带齿的最大荷。该力与传动转速有关传动装置中的传动带总传输载荷FU计算公式为:FU[N]=Fuspez▪ze▪bFU[N]=周向力Fuspez[N/cm]=载荷率Ze=与小带轮啮合的齿数Zemax=在传动计算中需要考虑的最大啮和齿数Zemax=BOOKINM为12个Zemax=BOOKINV为6个b[cm]=宽度特性PROFKLE带宽b[mm]带宽不锈钢HFEHighfexibilityFTzul[N]M型FBr[N]Ftzul[N]M型FBr[N]FTzul[N]M型FBr[N]T2002532301346030601275034001445003241801738039601650044001870005066502765063002625070002975007510070418701060045050100134905609014200603501501976082160柔性带轮最小齿数与惰轮最小直径T20带芯类型标准芳纶不锈钢HFE不锈钢同步带轮Zmin15152015在带齿上运转的惰轮dmin120mm120mm130mm100mm有反向弯曲的传动同步带轮Zmin25252020在传动带背面运转的惰轮dmin120mm120mm130mm100mm)