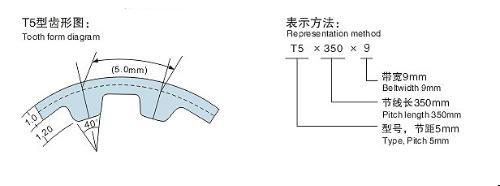

CNFULO伏龙公制方齿同步带T5 型(节距=5.00mm)标准规格表

CNFULO伏龙公制方齿同步带T5型(节距=5.00mm)标准规格表规格节线长(mm)模宽(mm)齿数T5×11511516023T5×13513515027T5×14014020028T5×1501506030T5×1651656033T5×1851856037T5×19019020038T5×2002008040T5×20520520041T5×21021020042T5×21521510043T5×22022020044T5×22522520045T5×24024020048T5×24524520049T5×2502506050T5×25525520051T5×26026020052T5×27027045054T5×27527545055T5×28028045056T5×29529545059T5×30030045060T5×30530545061T5×31031045062T5×32032045064T5×32532545065T5×33033045066T5×34034045068T5×34534545069T5×35035045070T5×35535545071T5×36536545073T5×37537520075T5×39039045078T5×40040045080T5×41041045082T5×42042045084T5×44544545089T5×45045045090T5×45545545091T5×47547545095T5×48048045096T5×48548545097T5×500500450100T5×505505450101T5×510510450102T5×520520450104T5×525525200105T5×540540450108T5×545545450109T5×550550450110T5×560560450112T5×570570.00450114T5×575575160115T5×580580450116T5×585585450117T5×600600160120T5×610610160122T5×620620200124T5×630630160126T5×635635450127T5×645645450129T5×650650450130T5×665665450133T5×675675160135T5×685685160137T5×690690120138T5×700700160140T5×710710450142T5×720720100144T5×725725450145T5×740740200148T5×750750220150规格节线长(mm)模宽(mm)齿数T5×780780160156T5790790450158T5×800800160160T5×805805450161T5×810810160162T5×815815450163T5*825825450165T5×840840450168T5×850850450170T5×860860160172T5×885885450177T5×900900200180T5×905905450181T5×910910450182T5×925925450185T5×940940200188T5×945945189T5×955955450191T5×990990150198T5×995995450199T5×10001000200200T5×10201020450204T5×10301030450206T5×10451045450209T5×10501050200210T5×10601060450212T5×10651065450213T5×10751075150215T5×11001100200220T5×11201120450224T5×11401140450228T5×12001200450240T5×12151215160243T5*12501250450250T5×12601260450252T5×12701270450254T5×12751275450255T5×13001300450260T5×13251325450265T5×13301330450266T5×13501350450270T5×13801380440276T5×13901390450278T5×14001400450280T5×14151415450283T5×14401440450288T5×14801480450296T5×15201520450304T5×16301630450326T5×17401740450348T5×1760176450352T5×18001800450360T5×18201820450364T5×18801880450376T5×19001900450380T5×19401940450388T5×19601960200392T5×20102010450402T5×21202120450424T5*21602160450432T5×22202220250444T5×22602260450452T5×22802280450456T5×25002500450500T5×27352735450547T5×28502850440570T5×30003000440600T5×30603060450612T5×31953195440639T5×32553255250651T5×32903290450658T5×35403540450708T5×37503750450750T5×40754075450815T5×48004800450960CNFULO伏龙同步带传动同时具有带传动、链传动和齿轮传动的共同特点,因此,在机械工程中的应用非常广泛,目不断扩大.由于同步带传动是通过带齿与轮齿的啮合传递运动和动力的,因此对现有齿形的完善和对新齿形的开发研究,一直是国内外学者研究的焦点之一为了提高研究效果,缩短试制周期,尽快将新产品推向市场,人们i1,在努力尝试着利用现代化的计算机乎段,通过同步带传动系统的仿真研究技术,验证新齿形同步带传动结构参数设计的i1确性,从而减少新齿形同步带传动开发过程中的重复性试制,降低成本,提高效率.本文以CNFULO伏龙新型平顶圆弧齿同步带齿形参数为基础,通过优化齿高,改善齿顶结构形式等方法,对新型高齿同步带传动进行啮合原理的分析和计算泪L仿真,研究结果表明其理论分析是正确的,结构参数切实可行.CNFULO伏龙高齿同步带的齿形为了更好地提高同步带的承载能力和使用寿命,降低传动噪声,提高运动精度,本文对新型平顶圆弧齿同步带的齿形作了一定改进,CNFULO伏龙设计了一种新型高齿圆弧齿同步带.这种高齿形圆弧齿同步带齿廓与传统圆弧齿同步带齿廓相比具有以下几个主要特点:(1)带齿高比传统STPD圆弧齿高度大14.75%,增大了带齿与轮齿的接触面积及啮合压力角,从而在单位承载强度不变的条件下提高了同步带承载能力(2)带齿高度比轮齿高度大6.06%,以减小带齿槽与轮齿顶间的压力,改善带齿间的磨损状态和承载层的受力状态,提高带的寿命(3)带齿顶开有四槽,可以使带与轮啮合时排除空气,降低噪声,同时,尸日槽还可以使齿顶层部变形,形成弹性齿顶,减小啮合冲击,改善啮合状态.结论(1)本文通过计算和仿真,分析比较了CNFULO伏龙新型高齿同步带的设计齿廓与据带轮齿廓求出的带轮共辘齿廓(即带的计算齿廓),结果发现一者吻合十分理想,并目带轮设计齿廓与据带齿廓求出的带齿共辘齿廓(即带轮计算齿廓)也相吻合,这说明新型高齿同步带与带轮的设计齿廓是合理的,能达到传动时的密切贴合度.(2)由所绘制的共辘齿廓可以看出,带模具滚刀及带轮滚刀齿廓的过渡曲线均未出现尖角,并目齿廓光滑连续,加工过程中避免了十涉或根切现象.(3)通过对传动过程的动态仿真可以直观地定性分析同步带传动不完全啮合过程中的啮合)