CNFULO伏龙同步带公制方齿T2.5 型(节距=2.50mm)模具规格表同步带传动的设计计算步骤/

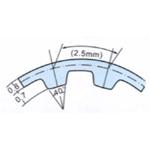

CNFULO伏龙同步带公制方齿T2.5型(节距=2.50mm)模具规格表规格节线长(mm)模宽(mm)齿数T2.5×102.5102.510041T2.5×12012010048T2.5×14514516058T2.5×147.5147.520059T2.5×15015016060T2.5×16016020064T2.5×16516520066T2.5×17017020068T2.5×177.5177.520071T2.5×187.5187.520075T2.5*19019020076T2.5×20020010080T2.5*22022020088T2.5×22522520090T2.5X227.5227.525091T2.5×23023020092T2.5×24524510098T2.5×265265200106T2.5×285285100114T2.5×300300100120T2.5×317.5317.5450127T2.5×322.5322.5450129T2.5×330330450132T2.5×335335100134T2.5×350350450140T2.5×380380450152T2.5*390390450156T2.5X400400450160T2.5×410410200164T2.5×420420450168T2.5×425425450170T2.5×470470450188T2.5×480480450192T2.5×500500450200T2.5×540540450216T2.5×620620160248T2.5×635635450254T2.5×650650450260T2.5×690690450276T2.5×705705450282T2.5×787.5787.5450315T2.5*905905450362T2.5×950950450380T2.5×975975450390T2.5*10401040450416T2.5*10901090450436T2.5×10951095450438T2.5×1127.51127.5450451T2.5×12951295450518T2.5×13451345450538T2.5×16701670450668CNFULO伏龙同步带的结构和尺寸规格(1).同步带结构CNFULO伏龙同步带一般由承载绳、带齿、带背和包布层组成。4.CNFULO伏龙同步带的设计计算(1).失效形式和计算准则CNFULO伏龙同步带传动主要失效形式有:(a)承载绳断裂原因是带型号过小和小带轮直径过小等。(b)爬齿和跳齿原因是同步带传递的圆周力过大、带与带轮间的节距差值过大、带的初拉力过小等。(c)带齿的磨损原因是带齿与轮齿的啮合干涉、带的张紧力过大等。(d)其他失效方式带和带轮的制造安装误差引起的带轮棱边磨损、带与带轮的节距差值太大和啮合齿数过少引起的带齿剪切***、同步带背的龟裂、承载绳抽出和包布层脱落等。在正常的工作条件下,CNFULO伏龙同步带传动的设计准则是在不打滑的条件下,保证同步带的抗拉强度。在灰尘杂质较多的条件下,则应保证带齿的一定耐磨性。(2).CNFULO伏龙同步带传动的设计计算步骤设计同步带传动的已知条件为:Pm需要传递的名义功率;n1、n2主从动轮的转速或传动比;(a)确定带的设计功率;(b)选择带型和节距;(c)确定带轮齿数和节圆直径;(d)确定同步带的节线长度、齿数及传动中心距;(e)校验同步带和小带轮的啮合齿数;(f)确定实际所需同步带宽度;(g)带的工作能力验算。)