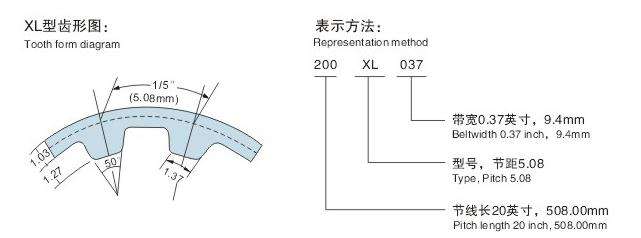

CNFULO伏龙梯形齿轻型英制XL 型(节距=5.080mm)同步带规格表

CNFULO伏龙梯形齿轻型英制XL型(节距=5.080mm)同步带规格表规格节线长(mm)模宽(mm)齿数44XL111.761002256XL142.241602860XL152.402003070XL177.802003572XL182.882003674XL187.962003776XL193.042003878XL198.122003980XL203.202004082XL208.282004184XL213.362004286XL218.442004388XL223.522004490XL228.602004592XL233.681004694XL238.762004796XL243.842004898XL248.9245049100XL254.0045050102XL259.0845051104XL264.1645052106XL269.2445053108XL274.3520054110XL279.4045055112XL284.4845056114XL289.5620057116XL294.6445058118XL299.7245059120XL304.8045060122XL309.8845061124XL314.9645062126XL320.0445063128XL325.1245064130XL330.2020065132XL335.2820066134XL340.3645067136XL345.4445068138XL350.5245069140XL355.6045070142XL360.6845071144XL365.7645072146XL370.8445073148XL375.9245074150XL381.0045075152XL386.0845076154XL391.1645077156XL396.2445078158XL401.3245079160XL406.4045080162XL411.4845081164XL416.5645082166XL421.6420083168XL426.7245084170XL431.8045085172XL436.8845086174XL441.9645087176XL447.0445088178XL452.1245089180XL457.2045090182XL462.2845091184XL467.3645092186XL472.4445093188XL477.5245094190XL482.6045095192XL487.6845096194XL492.7645097196XL497.8445098198XL502.9245099200XL508.00450100202XL513.08450101206XL523.24450103208XL528.32450104210XL533.40450105212XL538.48450106214XL543.56450107218XL553.72450109220XL558.80450110224XL568.96450112226XL574.04450113228XL579.13450114230XL584.20450115234XL594.36450117236XL599.44450118规格节线长(mm)模宽(mm)齿数240XL609.60450120244XL619.76450122248XL629.92160124250XL635.00450125256XL650.24450128260XL660.40450130264XL670.56450132266XL675.64450133270XL685.80450135274XL695.96450137276XL701.04450138280XL711.20450140282XL716.28200141286XL726.44450143290XL736.60200145300XL762.00200150304XL772.16450152306XL777.24450153310XL787.40450155316XL802.64450158320XL812.80450160322XL817.88450161326XL828.04450163330XL838.20450165336XL853.44450168340XL863.60450170344XL873.76450172348XL883.92200174350XL889.00450175352XL894.08450176356XL904.24450178360XL914.40450180362XL919.48450181364XL924.56200182370XL939.80450185372XL944.88450186376XL955.40200188380XL965.20450190384XL975.36450192390XL990.60450195392XL995.68450196400XL1016.00200200412XL1046.48450206414XL1051.56450207420XL1066.80450210424XL1076.90450212430XL1092.20450215432XL1097.28450216434XL1102.36450217450XL1143.00450225460XL1168.40200230480XL1219.20450240490XL1244.60450245492XL1249.68450246498XL1264.92450249514XL1305.56450257540XL1371.60450270550XL1397.00450275552XL1402.08450276560XL1422.40450280564XL1432.56450282566XL1437.64450283574XL1457.96450287580XL1473.20450290612XL1554.48200306630XL1600.20200315662XL1681.48450331670XL1701.80200335672XL1706.88450336686XL1742.44450343710XL1803.40450355720XL1822.88200360736XL1869.44450368788XL2001.52450394860XL2184.40450430888XL2255.52450444950XL24134504751014XL2575.564505071016XL2058.644505081032XL2621.284505161200XL3048.004506001220XL3098.804506101300XL3302.004506501494XL3794.764507472128XL5405.122001064CNFULO伏龙同步带传动是由一根内周表面设有等间距齿的封闭环形胶带和具有相应齿的带轮所组成,如图1_1所示。运转时,带的凸齿与带轮齿槽相啮合,来传递运动和动力。与其他传动粗比,同步带传动具有如下优点:1.工作时无滑动,有准确的传动比CNFULO伏龙同步带传动是一种啮合传动,虽然同步带是弹性体,但由于其中承受负载的承载绳具有在拉力作用下不伸长的特性,故能保持带节距不变,使带与轮齿槽能正确啮合,实现无滑差的同步传动,获得精确的传动比。2.传动效率高,节能效果好由于CNFULO伏龙同步带作无滑动的同步传动,故有较高的传动效率,一般可达0.98。它与三角带传动相比,有明显的节能效果,可用如下实例作证明。从以上数例看出,CNFULO伏龙同步带传动在节能上有很大潜力,因此采用同步带传动可获得较高的经济效益。3,传动比范围大,结构紧凑CNFULO伏龙同步带传动的传动比一般可达到10左右,而且在大传动比情况下,其结构比三角带传动紧凑。因为同步带传动是啮合传动,其带轮直径比依靠摩擦力来传递动力的三角带带轮要小得多,此外由于CNFULO伏龙同步带不需要大的张紧力,使带轮轴和轴承的尺寸都可减少。所以与三角带传动相比,在同样的传动比下,同步带传动具有较紧凑的结构。4,维护保养方便,运转费用低由于CNFULO伏龙同步带中承载绳采用伸长率很小的玻璃纤维、钢丝等材料制成,故在运转过程中带仲长很小,不需要像三角带、链等经常调整张紧力。此外,同步带在运转中也不需要任何润滑,所以维护保养很方便,运转费用比三角带、链、齿轮要低碍多。5,恶劣环境条件下能正常工作在具有灰尘杂质、水及腐蚀介质的恶劣工作条件下,链条易生锈、磨损,三角带会产生打滑,而CNFULO伏龙同步带传动却能适应这些条件。由于它是啮合传动,在有雨水情况下不会打滑,而且水是橡胶良好的润滑剂,反而可减少带的磨损。在有灰尘杂质时,由于同步带带齿进入带轮轮槽时,带齿将挤压原留在轮槽内的空气,使受压的空气向轮槽两侧排出,这种空气挤压将同时起到清理啮合表面、带走灰尘杂质的作用,从而减少了同步带的磨损。此外CNFULO伏龙同步带有较高的耐腐蚀性,耐热性,在高温、有腐蚀气体情况下仍能正常工作。)