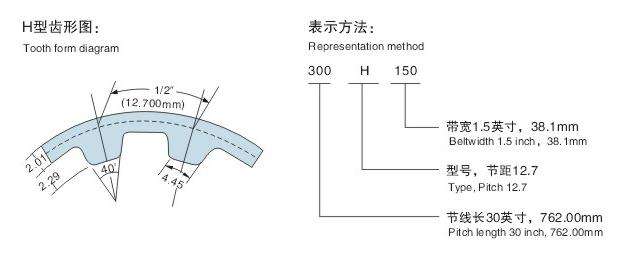

CNFULO伏龙同步带英制梯形齿H 型(节距=12.70mm)规格表和同步带传动的各类分析

CNFULO伏龙同步带英制梯形齿H型(节距=12.70mm)规格表规格节线长(mm)模宽(mm)齿数145H368.345029185H469.945037200H50845040205H520.745041210H533.445042220H558.845044225H571.545045230H584.245046240H609.645048245H622.345049250H63545050255H647.745051260H660.445052270H685.845054280H711.245056285H723.945057290H736.645058300H76245060310H787.445062315H800.145063320H812.845064325H825.545065330H838.245066335H850.945067340H863.645068345H876.345069350H88945070355H910.745071360H914.445072365H927.145073370H939.820074375H952.545075380H965.245076390H990.645078395H1003.345079400H101645080405H1028.745081410H1041.445082420H1066.845084425H1079.545085430H1092.245086435H1104.945087440H1117.645088445H1130.345089450H114345090455H1155.745091460H1168.420092465H1181.145093470H1193.845094480H1219.245096485H1231.945097490H1244.645098500H1270450100510H1295.4450102515H1308.1450103520H1320.8190104525H1333.5200105530H1346.2450106535H1358.9450107540H1371.6450108550H1397450110555H1409.7450111560H1422.4450112565H1435.1450113570H1447.8450114580H1473.2450116585H1485.9450117590H1498.6450118600H1524450120605H1536.7450121610H1549.4450122615H1562.10450123620H1574.8450124625H1587.5450125630H1600.2450126640H1625.6450128650H1651450130660H1676.4450132670H1701.8450134680H1727.2200136690H1752.6450138695H1765.3450139700H1778450140710H1803.4200142720H1828.8450144725H1841.5450145规格节线长(mm)模宽(mm)齿数730H1854.2450146740H1879.6450148750H1905450150755H1917.7500151760H1930.4450152770H1955.8450154780H1981.2450156785H1993.9200157800H2032450160810H2057.4200162820H2082.8450164830H2108.2450166840H2133.6230168850H2159450170860H2184.4250172880H2235.2200176895H2273.3450179900H2286450180920H2336.8450184930H2362.2450186950H2413450190960H2438.4450192970H2463.8450194980H2489.2450196985H2501.9450197895H2273.34501971000H25404502001020H2590.82002041030H2616.24502061050H26674502101070H2717.84502141085H2755.92502171100H27944502201120H2844.84502241125H2857.54502251130H2870.22002261140H2895.62002281150H29214502301170H2941.84502341175H2984.54502351200H30484502401250H31754502501260H3200.44502521270H3225.82502541300H32024502601325H3365.52502651350H34294502701350H34294502701360H3454.44502721380H3505.204502761400H35564502801440H36574302881450H36832502901460H3708.44502921500H38104403001510H3835.44403021520H3860.84503041535H3898.94403071550H39374403101560H3962.44403121600H40644403201630H4140.24403261660H4216.44403321680H4267.24403361700H43184403401740H4419.64503481750H44454403501765H4483.14503531775H4508.54503551850H46994503701855H4711.72503711860H4724.44403721920H4876.84503841995H5067.34503992010H5105.44304022050H52074504102090H5308.64404182100H53344504202120H5384.83404242160H5486.44004322200H55882404402210H5613.44504422320H5892.84404642355H5981.74504712360H5994.44404722385H6057.94404772440H6197.64404882475H6286.54404952500H63504405002600H66044405202680H6807.24505362695H6845.34245392700H68584505402720H6908.8450544CNFULO伏龙同步带传动:利用张紧在带轮上的传动带与带轮的摩擦或啮合来传递运动和动力。分类-根据传动原理的不同1.摩擦传动型2.啮合传动型摩擦传动型CNFULO伏龙同步带传动结构简单、传动平稳、具有过载保护功能,但不能保证恒定的传动比,传动精度较低。啮合传动型(同步带)CNFULO伏龙同步带传动比准确,速比恒定,传动比范围大,允许线速度高,传动效率可达98%,结构紧凑。传动带张紧静止时传动带应张紧在带轮上,使得带与带轮接触间产生一定的压力。带两边拉力相等,为初拉力F0常用张紧方法:调节两轮中心距、利用张紧轮二、CNFULO伏龙同步带传动的受力分析紧边拉力F1:带在进入主动轮一边被拉紧为紧边,拉力由F0增加为F1。松边拉力F2:带在进入从动轮一边被放松称为松边。拉力由F0减少为F2。有效拉力Ft:带传动所能传递的有效圆周力。Ft=F1-F2当传递的圆周力超过此极限值时,带将在轮面上打滑。避免打滑的条件:有足够的fv?值和F0值三、带传动的应力分析CNFULO伏龙同步带传动工作时的应力:由紧边和松边拉力所产生的应力;由离心力产生的应力以及由于带在带轮上弯曲产生的应力。由紧边和松边拉力产生的应力,由离心力产生的应力-作用于带的全长带在带轮上弯曲产生的弯曲应力最大应力发生在带紧边进入小带轮处。四、弹性滑动、打滑和滑动率CNFULO伏龙同步带弹性滑动:带是弹性体,受拉力作用后产生拉伸弹性变形,工作时由于存在紧边拉力,松边拉力,带在通过带轮时拉伸变形发生变化,使带与带轮之间产生相对滑动,这种滑动与带的弹性变形有关。弹性滑动是由拉力差引起的,只要传递圆周力,弹性滑动就不可避免。打滑:当外载荷大到一定值时,带与带轮间产生全面滑动;打滑是由过载引起的全面滑动,只要限制载荷,就可以避免,而且应当避免。滑动率-从动轮速度的降低率带传动的实际传动比)