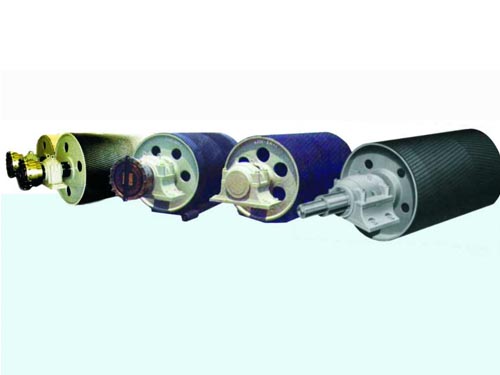

NC柔性滚筒

柔性结构滚筒的特长:自从二十世纪六十年发钢丝胶带之后,胶带输送机迎来大容量、长距离输送的时代,为了满足大输送量的要求,经反复研究试验,***终将滚筒结构从钢性结构转换为柔性结构。柔性结构滚筒从外观看与刚性结构滚筒基本相同,但是其结构上有着本质的区别,柔性结构滚筒允许滚筒在许用应力范围内产生绕曲弯形,用以吸收一部分动能,缓和局部应力集中,进而提高滚筒整体的疲劳强度,延长使用寿命。我公司制造的柔性结构滚筒使用寿命可确保连续运转六年以上。柔性结构滚筒的设计要点:滚筒转动时产生的弯矩和扭矩,特别是交变动载荷作用在滚筒上,致使滚筒受力非常复杂。因此,设计时必须***计算疲劳强度。FeaturesofFlexibleStructurePulleysSincethedevelopmentofsteelwirebeltinthe60softhe20thcentury,beltconveyorhascomeintotheageoflargecapacityandlongdistancecarrying.Inordertomeettheneedsoflargecapacitycarrying,passthroughresearchandtesttimeaftertime,wechangethepulleyfromrigidstructuretoflexiblestructure.Theappearanceofrigidstructurepulleysandflexiblestructurepulleysarebasicallysimilar.buttheirinnerstructureareabsolutelydifferent.Forflexiblestructurepulleys,flexibilitydistortionisallowedinthefieldofallowablestresstoabsorbpartialkineticenergy,relaxlocalstressconcentration,andaccordinglyenhancethewholefatigueintensityofpulleysandextendlife-span.Itcanensureofmorethansixyearsofcontinuousoperation.DesignEssentialsotFlexibleStructurePulleysOnaccountofbendingmomentandtorqueproducedfromtherunningofpulleys,especiallythealternantfluctuantloadsactingonpulleys.thecompositionofforceputonpulleysisverycomplicated.Therefore,thefatigueintensitymustbeaccuratelycalculatedduringtheprocessofdesign.)