OPTIBELT欧皮特中型改进型AT10齿聚氨酯同步带特性和AT10同步带轮齿数直径数据表

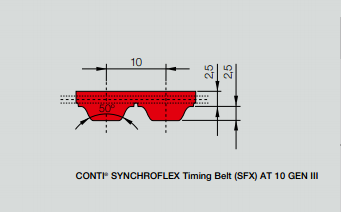

OPTIBELT欧皮特中型改进型AT10齿聚氨酯同步带特性▪带有钢制带芯或复合材料凯夫拉的聚氨酯同步带。▪公制节距10mm▪齿形与尺寸均经过优化,可保证载荷均匀分布且变形最小。▪高耐受性与低延展性钢制带芯可保证高稳定性与低延长率。▪减少多边形影响和传动振动。▪特别适合轴向与角度定位精度较高的线性传动装置与轻载动力的传输应用。▪可提供双面齿的产品▪根据要求可提供负长度公差▪宽度公差:±0.5[mm]▪长度公差:±0.5[mm/m]▪厚度公差:±0.3[mm]OPTIBELT欧皮特中型改进型AT10齿聚氨酯同步带技术参数带宽b[mm]允许拉伸载荷M型FTzul[N]允许拉伸载荷V型FTzul[N]断裂载荷M型FBr[N]弹性刚度比Cspez[N]重量[kg/m]162450122595006125000.092538281914148449570310.1532490024501900012250000.1950765638282968819140630,30751148457424453128710940.441001531376565937538281250.5915022969114848906357421880.74根据要求可提供其他宽度。带齿剪切强度rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]075,7080053,70190042.02450029.132074.5990052.21200041.28500027,504073.55100050.85220039.89550026.016072.57110049.59240038.62600024.658071.65120048.43260037.44650023,4010070.78130047.34280036.33700022.2320067.13140046.32300035,30750021.1430064.18144045.93320034.33800020.1240061.53150045.36340033.41850019.1550059.21160044.46360032.55900018.2460057.16170043,60380031.72950017.3870055.34180042.79400030.941000016.56载荷率Fuspez是指在各种工作条件下1cm宽的单个带齿的最大荷。该力与传动转速有关传动装置中的传动带总传输载荷FU计算公式为:FU[N]=Fuspez▪ze▪bFU[N]=周向力Fuspez[N/cm]=载荷率Ze=与小带轮啮合的齿数Zemax=在传动计算中需要考虑的最大啮和齿数Zemax=欧皮特开口带M为12个Zemax=欧皮特环形带V为6个b[cm]=宽度OPTIBELT欧皮特中型改进型AT10齿聚氨酯同步带特性PROFKLE带宽b[mm]带宽不锈钢HFEHighfexibilityFTzul[N]M型FBr[N]FTzul[N]M型FBr[N]FTzul[N]M型FBr[N]AT1001619007900180075002000850002532301343030601275034001445003241801738039601650044001870005066502765063002625070002975007510070418701060045050100134905609014200603501502033084530柔性OPTIBELT欧皮特中型改进型AT10齿同步带轮最小齿数与惰轮最小直径AT10带芯类型标准芳纶不锈钢HFE无反向弯曲的传动同步带轮Zmin15151815在带齿上运转的惰轮dmin50mm50mm100mm50mm有反向弯曲的传动同步带轮Zmin25202515在传动带背面运转的惰轮dmin120mm120mm100mm80mmOPTIBELT欧皮特中型改进型AT10齿同步带轮齿数直径数据表zdadwzdadwzdadwzdadw1855.4557.2947147.75149,6076240.05241.94105332.35334.211958,6060.4848150.95152.7877243.25245.09106335.55337,402061,8063.6649154,10155.9778246,40248.24107338.75340.582165,0066.8450157,30159.1579249,60251.46108341,90343.762268.1570.0351160,50162.3380252,80254.64109345,10346.952371.3573,2052163.65165.5281255.95257.82110348,30350.132474.5576.3953166.85168,7082259.15261,00111351.45353.312577,7079.5854170.05171.8883262,30264.19112354.65356,502680,9082.7655173,20175.0684265,50267.37113357,80359.682784,1085.9556176,40178.2585268,70270.52114361,00362.862887.2589.1257179,60181.4386271,90273.74115364.19366.042990.4592.2158182.75184.6187275.05276.92116367.39369.233093.6595.4959185.95187,8088278.25280,10117370.56372.413196,8098.6760189,10190.9889281.45283.28118373.74375.5932100,00101.8661192,30194.1690284,60286.47119376.93378.7833103,20105.0462195,50197.3591287,80289.65120380.11381.9634106,40108.1963198.65200.5392291,00292.8435109.55111.4164201.85203.7193294,20296.0236112.75114.5965205.05206,9094297.35299,2037115,90117.7766208,20210.0895300.55302.3938119,10120.9567211,40213.2696303,70305.5739122,30124.1468214,60216.4497306,90308.7540

上海汇昕传动系统厂

| 姓名: | 江云 女士 |

| 手机: | 13917794200 |

| 业务 QQ: | 2313737743 |

| 公司地址: | 上海市奉贤区沪杭公路3281号 |

| 电话: | 021-57446367 |

| 传真: | 021-57446367 |