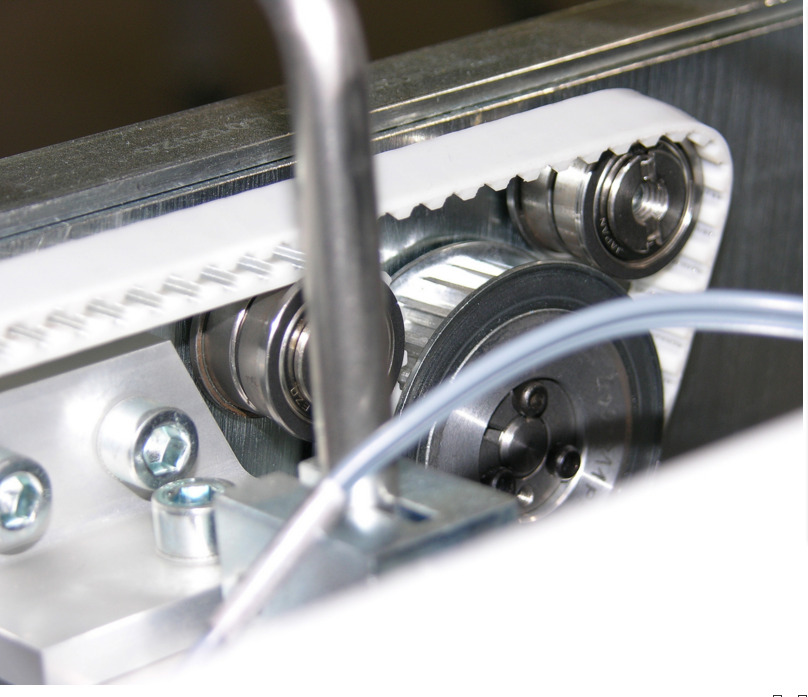

欧皮特聚氨酯PU同步带公制T5特性和公制T5同步带轮数据表

T5欧皮特聚氨酯PU同步带公制T5特性▪带有钢制带芯的聚氨酯同步带▪符号DIN7721T1标准的梯形齿形▪公制方齿节距5mm▪非常适合高柔性传动的应用▪广泛用于输送、线性传动和轻载动力传输应用▪可提供双面带齿的产品▪宽度公差:±0.5[mm]▪长度公差:±0.5[mm/m]▪厚度公差:±0.2[mm]T5同步带技术参数带宽b[mm]允许拉伸载荷M型FTzul[N]允许拉伸载荷V型FTzul[N]断裂载荷M型FBr[N]弹性刚度比Cspez[N]重量[kg/m]103201601250800000.0211651225620001280000.0342580040031252000000.05332102451240002560000.06750160080062504000000.105752400120093756000000.15810032001600125008000000,210根据要求可提供其他宽度。带齿剪切强度rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]rpmFUspez[N/cm]024,7080017.02190014.21450011.252024.0790016.65200014.03500010.884023.53100016.32220013.71550010.556023.05110016.01240013.42600010.248022.64120015.73260013.1465009.9610022.28130015.47280012.8970009,7020020,90140015.22300012.6575009.4630019.89144015.13320012.4380009.2340019,10150015,00340012.2285009.0150018.45160014.78360012.0390008.8160017.91170014.58380011.8495008.6270017.44180014.39400011.66100008.44载荷率Fuspez是指在各种工作条件下1cm宽的单个带齿的最大荷。该力与传动转速有关传动装置中的传动带总传输载荷FU计算公式为:FU[N]=Fuspez▪ze▪bFU[N]=周向力Fuspez[N/cm]=载荷率Ze=与小带轮啮合的齿数Zemax=在传动计算中需要考虑的最大啮和齿数Zemax=OPTIBELT开口同步带M为12个Zemax=OPTIBELT环形同步带V为6个b[cm]=宽度OPTIBELT公制T5特性PROFILE带宽b{mm}芳纶带芯FTzu[N]M型FBr[N]T50108403,360161,1904,760251,9607,840322,52010,0800504,06016,240756,61024,6401008,26033,040柔性OPTIBELT公制T5同步带轮最小齿数与惰轮最小直径T5带芯类型标准无反向弯曲的传动同步带轮Zmin10在带齿上运转的惰轮dmin30mm有反向弯曲的传动同步带轮Zmin15在传动带背面运转的惰轮dmin30mm欧皮特T5型同步带轮数据表zdadwzdadwzdadwzdadw1015.0515.923961.2562.0968107.4108.2697153.55154.421116.6517.514062.8563.6669109,00109.8598155.15156.021218.2519,104164,4065.2770110,60111.4499156.75157.611319.8520,704266,0066.8671112,20113.03100158.35159,201421.4522.294367,7068.4672113.75114.62101159.95160.791523.0523.884469,2070.0573115.35116.22102161.55162.381624,6025.474570,8071.6474116.95117.81103163,10163.971726,2027.064672,4073.2375118.55119,40104164,70165.571827,8028.654773.9574.8276120.15120.99105166,30167.161929,4030.254875.5576.4277121.75122.58106167,90168.752031,0031.834977.1578.0178123,30124.18107169,50170.342132,7033.435078.7579,6079124,90125.77108171,10171.942234.2535.025180.3581.19

上海汇昕传动系统厂

| 姓名: | 江云 女士 |

| 手机: | 13917794200 |

| 业务 QQ: | 2313737743 |

| 公司地址: | 上海市奉贤区沪杭公路3281号 |

| 电话: | 021-57446367 |

| 传真: | 021-57446367 |