BRECO同步带同步带的正常磨损和失效以极BRECOFLEX同步带轮跳动导致同步带失效的原因

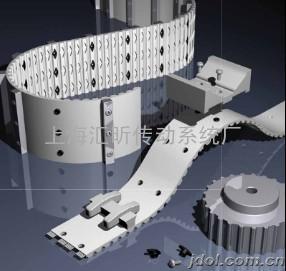

Runtwotothreeyearsafterthetimingbeltdonotneedtotakeanyremedialmeasures.Timingbeltlifeduetotheapplicationofdifferentandvariousobjectivefactors,therearesignificantchanges.Factorsaffectingthetimingbeltlife,includingthetran***issionpowerlevel,theenvironment,timingbeltinstallationtensionwithwithroundmatch,thequalitylevelofthepulley,orevenhowtocutintwotothreeyearsafterthetimingbeltoperation,whenitscorelinesoffatigueInlife,timingbeltfailureisanormalsituation.Afteralongoperation,thetimingbeltduetothewiretoreachthefatiguelifeandfailure,whichbelongstotheidealtimingbeltfailuremode.Figure1isamixed45-degreeanglejaggedfracturebelt,whichistypicaltimingbeltwiretoreachthenormalfatiguelife.Synchronousbelttoothwillalsofail,butthisisnottheidealtimingbeltfailuremode.Inthelong-termoperation,althoughthetimingbeltisabletomaintainthesizeandshapeoftheinitial,butthetimingbelttoothwearappear.Exposedfibermakestimingbelttimingbeltcanvastoothlooksroughandfrizzy.BRECO同步带同步带的正常磨损和失效运行二到三年后的同步带不需要再采取任何改善措施。同步带寿命会由于应用的不同,以及各种客观因素而有较大变化。影响同步带寿命的因素包括传输功率等级,环境,同步带安装张力,带与轮的匹配,带轮的质量水平,甚至是如何切在同步带运转二到三年后,当其芯线达到疲劳寿命时,同步带失效是属于正常情况。在经过长期运转后,同步带由于芯线达到疲劳寿命而失效,这属于理想的同步带失效模式。图1是一个参差不齐的45度角的锯齿状断裂同步带,这是典型的同步带芯线达到正常的疲劳寿命造成的。同步带的齿部也同样会失效,但是这不属于理想的同步带失效模式。在长期的运转下,虽然同步带能够保持初始的大小和形状,但是同步带齿部会出现磨损。同步带帆布的外露纤维会使同步带齿部看起来粗糙毛燥,pulleysbeatingleadtotimingbeltfailureTimingbeltpulleystowearaconeinstalled,orinstalledafterre-reaming,oftenpronetobeatingthe***allestpulleylight-holebasis.Howtoinstallinaccordancewiththestanda***,andhowtoensuretheshaftholewithunderstandingorc***ultationtimingbeltrunsinapulleysystemrunoutwhenthetimingbelt,timingbeltpulleysrotatinginthebelttechnicaldocumentationofinspectionWeixinZhangtightpowerofthecyclicalriseandfall.Beatingthemorepowerful,highermaximumtensionontherise.Affected,sothatthebottomteethlookliketobecrushed,asshownbelow.Crushedwiththepossibleissimilartothephenomenonofrunninginthemoderatesizepulleybelttensionistoohigh.Extremecyclicalchangesintensiontimingbeltteethoftenresultintearingortimingbelttensilefracture.BRECO同步带同步带轮跳动导致同步带失效同步带轮往锥套上安装,或在***小的带轮光孔基础上进行再扩孔后安装时,往往容易发生跳动。如何按照标准进行安装,以及如何确保轴孔的配合,在查阅韦欣同步带技术文档进行相关了解或者咨询同步带运行在径向跳动的带轮系统中时,同步带轮旋转时BRECO同步带的张紧力会周期性的升降。跳动的越厉害,***大张紧力就升的越高。受此影响,使齿底看起来像被碾碎一样,如下图。碾碎的带体可能与在适度尺寸带轮中而运行的同步带张紧力过高所导致的现象相类似。而极端周期性的张力变化常常导致同步带齿部撕裂或同步带拉伸性断裂。)