BRECO/BRECOFLEX同步带同步带轮不合格导致同步带失效AND同步带同步带轮不平行导致同步带

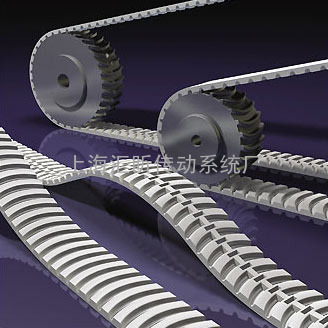

BRECO/BRECOFLEX同步带同步带轮不合格导致同步带失效在腐蚀性空气下,同步带轮***容易被迅速磨损。严重磨损的同步带轮通常表现为轮槽磨损和同步带轮加工外径的减少。磨损同步带轮导致同步带失效典型的表现为同步带齿底磨光性损伤和齿部区域性尺寸变形。经过硬镀铬过的同步带轮可以延长其在腐蚀性空气中的寿命。另一种情况,如果替换后的新同步带的寿命比以前的同步带低,也要仔细检查下同步带轮是否过度磨损。无论是由于同步带轮的生产不符合标准或磨损到超出标准造成的同步带过早失效通常很难识别。部分是因为当同步带失效时,几乎很少有人去仔细地检查同步带轮,而通常都认为是同步带的自身问题。同步带在尺寸有问题的同步带轮上运行时,其齿部侧面会出现高度磨损,同时同步带侧面的帆布成模糊的绒毛状或片状。BRECO/BRECOFLEX圆弧齿同步带(HTD,STD,RPP)运行在直径过小的同步带轮系统中,会使带体大面积分裂和同步带拉伸性断裂,如图1所示。梯形齿(XL,L,H)同步带通常是齿根裂缝或带齿剪切,然而同步带拉伸性断裂倒不常见。张紧力过高可能导致同步带轮更多的磨损。运行时间很长的同步带的齿面或帆布有时已经完全磨损掉,这种情况就预示同步带轮磨损也已经产生。同步带磨损后会使其芯线与同步带轮接触,从而造成同步带轮的外周轮槽也磨损。同步带轮的齿顶有凸起是同步带轮磨损后的标志,如图2所示。注意:磨过的表面非常尖锐***好用螺丝起子去感觉,以防手被划伤。这种情况下,应该更换同步带轮。BRECOtimingbelttimingbeltpulleysarenotparalleltothetimingbeltfailureTimingbeltrunningonatimingbeltpulleysonbothsidesh***eribsandatimingbeltpulleysonbothsidesofribswhenthetwotimingbeltpulleysarenotparallel,thenthetimingbeltwillbepartofthetimingbeltpulleysmovewithnoribs,noribstimingbeltwheelinthispartofthetimingbeltwillbearalltheloadandmaybeintherunningforsometimetoproduceaconcentratedwearareas.Theconcentrationofmostofthetoothsurfacewear,nowearelsewhere.Cracksmayh***erootsinthewearareasbelow.Timingbeltstrengthortoothsurfacefatiguewilleventuallyleadtoprematuretimingbeltfailure.Thehigh-fibertensionledtothetimingbeltsideofseriouswearandtear.Thetimingbeltrunninginthenotparalleltotheribstimingbeltpulleys,timingbelthasbeensqueezedintwooppositeribswillcauseseverewearofthetimingbeltonbothsides.Inthiscase,thetimingbeltfromthetoothrootcracksorfrombothsidesofthetear.Thistearwilleventuallybeextendedtothewholetimingbelt,resultinginsynchronousbelttoothshear.Thetimingbeltatruntime,thetimingbeltaxleatanangle,ortimingbelttooth-shapedtaperproblemexistsintheprocessingloadunevenlyappliedtothetimingbeltonthetoothedunevenextrusion.Thetimingbeltfailureoftenbegintotearfromthetoothrootcracking,orfromcarryingtensionthetimingbeltsideandextendedtothewholetimingbeltwidth,eventuallyleadingtothetimingbelttoothshear.Relativelylargeduetofibertension,timingbeltsqueezeserioussidemayalsoappear***iouswearandtear,andthetimingbeltmayclimboutoforrolledriboftheDepartmentoftimingbeltpulleys.BRECO同步带同步带轮不平行导致同步带失效同步带运行在一个同步带轮两边都有挡边和一个同步带轮两边都没有挡边时,如果两个同步带轮不平行,那么同步带会部分向没有挡边的同步带轮移动,无挡边同步带轮中这部分同步带将会承受全部负载并且可能在运行一段时间后产生一个集中磨损区域。大部分齿面的集中磨损,其它地方没有磨损。在磨损区域下面可能会有根部裂缝。同步带强度或齿面疲劳***终都会导致同步带的过早失效。高纤拉力导致了同步带一边严重的磨损。BRECO同步带运行在不平行有挡边的同步带轮时,如果同步带被挤压在两个相对的挡边中,会导致同步带两侧严重磨损。在这种情况下,同步带会从齿根裂缝或从两侧撕裂。这种撕裂***终会扩展到整个同步带,导致同步带齿部剪切。同步带在运行时,同步带轮轴成一定角度,或同步带轮齿形在加工时存在锥度问题,由于施加在同步带上的负载不均匀,带齿之间会出现不均匀的挤压。同步带失效经常从齿根开裂处或从承载张力***大的同步带侧面开始撕裂并扩展到整个同步带宽度,***终导致同步带齿部剪切。由于纤拉力比较大,同步带挤压严重的一侧可能也会出现明显的磨损,并且同步带有可能爬出或滚到同步带轮挡边之处。)