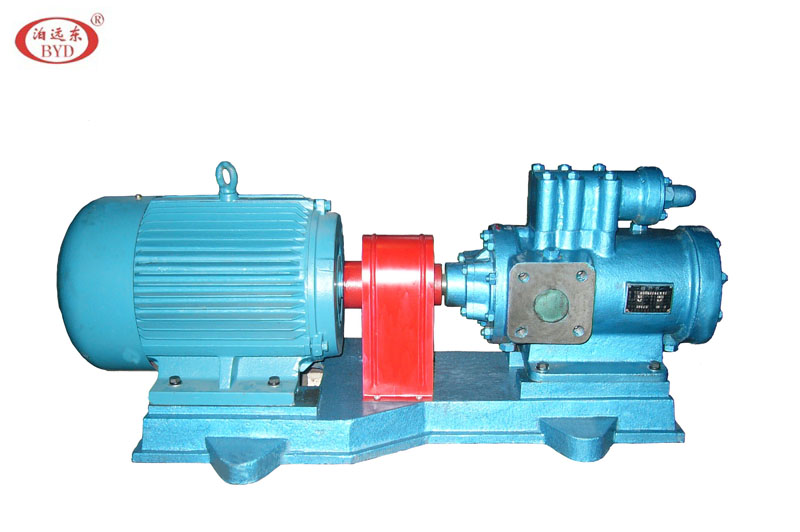

深孔镗床冷却油泵3GR42×6AW23型螺杆泵

价格:4860.00

深孔镗床冷却油泵3GR42×6AW23型螺杆泵选好泵是用好泵基础,24小时热线服务电话:13610186785常经理三螺杆泵/3G三螺杆泵1.特点2.适用介质和性能范围3.结构4.系列说明5.材料代码3GR普通型三螺杆泵适用范围:20-150cst润滑油类及润滑性液体流量0.3-94m3/h,最高工作压力60bar详细参数3GC船用型卧式单吸三螺杆泵适用范围:20-150cst润滑油类及润滑性液体流量0.3-94m3/h,最高工作压力60bar3GCLS立式柱脚双吸三螺杆泵适用范围:20-150cst润滑油类及润滑性液体流量范围:88-306m3/h最高工作压力:8bar3GCL立式柱脚单吸三螺杆泵适用范围:20-150cst润滑油类及润滑性液体流量范围:4-96m3/h最高工作压力8bar3GS卧式双吸三螺杆泵适用范围:20-150cst润滑油类及润滑性液体流量范围:80-590cst最高工作压力16bar●特点:3G三螺杆泵(螺杆输油泵)包括3G通用型,3GC船用型及特殊型。3G三螺杆泵是转子式容积泵,由于主动螺杆与从动螺杆上螺旋槽相互啮合及它们与衬套三孔内表面的配合,得以在泵的进出口之间形成数级动密封腔室,这些动密封腔室将不断把液体由泵进口轴向移动到泵出口,并使所输液体逐级升压,从而形成一个连续、平稳、轴向移动的压力液体。●3G三螺杆泵(螺杆输油泵)适用介质及性能范围:3G三螺杆泵所输液体为各种不含固体颗粒,无腐蚀性油类及类似油的润滑性液体,所输液体粘度为1.2~100°E(3.0~760cst),高粘度液体亦可通过加温降粘后输送。流量范围0.2~590m3/h,最高工作压力100bar,最高温度150℃。●3G三螺杆泵(螺杆输油泵)结构:1、结构简单:具有多种结构形式,一般小流量0.2~6.5m3/h,泵的泵体和衬套合为一体(统称泵体),轴封为机械密封。中等流量以上的泵衬套为一单独的零件固定于泵体内,大流量泵多制成双吸结构卧式安装,轴封根据输送介质的不同有机械密封和填料密封两种。3G船用泵的安装形式有卧式和立式两种,原动机为交、直流船用电动机。2、寿命长:3G三螺杆泵的主动螺杆由电动机驱动,主、从杆之间没有机械接触,而由所输压力液体驱使从杆绕轴心线自转,主、从杆之间、螺杆与衬套之间皆有一层油膜保护,因而泵的机械摩擦极小,寿命堪称半永久性。3、所输液体在3G三螺杆泵内作轴向匀速直线运动,故压力脉动小,流量稳定,噪音低,由于转动部件惯性小,则起动力矩和振动很小。4、3G三螺杆泵具有高吸入能力。5、为保证3G三螺杆泵、电机及管路系统的安全,中等流量以上的螺杆泵均带有安全阀,当压力超过安全阀的设定压力时,高压油将回流至泵的进油口。●3G三螺杆泵系列说明系列特征系列代号结构形式适用范围性能范围流量最高工作压力滑油系列3G3GC卧式单吸20~150cst润滑油类及润滑性液体0.3-94(m3/h)60(bar)3GS3GCS卧式双吸80-590163GCG立(悬挂)式单吸10-9682GCL立式柱脚型单吸4--9683GCLS立式柱脚型双吸88-3068燃油系列3Gr3GCr卧式单吸3~365cst轻重质燃油类0.3-9460①25②3GSr3GCSr卧式双吸80-59016高粘油系列3GN卧式单吸365~760cst高粘度油类1.0-4025●3G三螺杆泵材料代码性能表(3G\3Gc\3Gr\3GCr(20-36))●性能表(3G\3Gc\3Gr\3GCr(36-42))●性能表(3G\3Gc\3Gr\3GCr(50-70))●性能表(3GR70×3)●性能表(3G\3Gc\3Gr\3GCr(85-100))●性能表(3GS\3GCS\3GSr\3GCSr(100-200))●性能表(3GCG(50-110))|●性能表(3GCL(50-110))●性能表(3GCLS(100-160))●性能表(3GN(36-110))●性能表(3G25╳4C-3G70╳3C)●性能表(3G\3Gc\3Gr\3GCr(20-36))泵型号流量压力功率P(千瓦)电动机型号米3/时升/分轴功率电动机功率3G3GC3Gr3GCr(75cst)①20×41.00.816.613.310250.681.10.751.5801-2B390S-2B30.40.36.6510250.30.50.550.75801-4B3802-4B320×60.80.613.31040601.72.72.2390L-2B3100L-2B30.30.253.340600.81.351.11.590S-4B390L-4B325×42.01.6332610251.12.21.5390S-2B3100L-2B30.80.6131010250.51.10.751.5802-4B390L-4B325×61.61.4262340603.4545.5112M-2B3132S1-2B30.60.4106.640601.62.52.23100L1-4B3100L2-4B330×43.63.2605310251.93.82.2490L-2B3112M-2B31.61.2262010250.91.91.52.290L-4B3100L1-4B330×63.22.8534640605.89.37.511132S2-2B3160M1-2B31.20.8201340602.74.645.5112M-4B3132S-4B336×46.5610810010253.26.247.5112M-2B3132S2-2B32.82.4464010251.63.12.24100L1-4B3112M-4B33Gr3GCr(3cst)②20×40.80.313.3510100.60.20.750.55801-2B3801-4B320×60.60.2103.325251.10.41.50.7590S-2B3802-4B325×41.60.6261010101.10.51.50.7590S-2B3802-4B325×61.40.4236.625252.21.131.5100L1-2B390L-4B330×43.21.2532010102.00.92.21.590L-2B390L-4B330×62.80.8461325253.81.75.52.2132S1-2B3100L1-4B336×462.41004010103.21.642.2112M-2B3100L1-4B3●性能表(3G\3Gc\3Gr\3GCr(36-42))泵型号流量压力P功率P(千瓦)允许吸上真空高度(米)电动机型号米3/时升/分轴功率电动机功率3G3GC3Gr3GCr(75cst)36×6A651008340601015.51518.55160M-2B3160L-2B32.42403340604.87.75.5115.5132S-4B3160M-4B342×4A10.51017516610254.99.55.5154.5132S-2B3160M2-2B34.84.2807010252.44.745.55112M-4B3132S-4B342×6A10916615040601621.518.5304.5160L-2B3200L1-2B34.23.6706040607.51011155160M-4B3160L-4B33Gr3GCr(3cst)36×6A583256.27.54132S2-2B3233253.14112M-4B342×4A10166104.55.54132S-2B34270102.44112M-4B342×6A91502510.5154160M2-2B33.660254.85.5132S-4B3●性能表(3G\3Gc\3Gr\3GCr(50-70))泵型号流量压力P转速n转/分功率P(千瓦)允许吸上真空高度(米)电动机型号米3/时升/分轴功率电动机功率3G3GC3Gr3GCr(75cst)50×217.51629126661029005.28.15.5114.5132S1-2B3160M1-2B38.27.513612561014502.64.035.55100L2-4B3132S-4B350×4A17.5162912661625290011.616.51518.54.5160M-2B3160L-2B38.27.5136125162514505.88.27.5115132M-4B3160M-4B370×22423400383610145079.811154.5160M-4B3160L-4B315142502336109704.86.55.57.55132M2-6B3160M-6B370×42422400366162514501420.518.5224.5180M-4B3180L-4B3151425023316259707.513.51118.55160L-6B3200L1-6B33Gr3GCr(3cst)50×216266429003.35.54132S1-2B37.5125414501.72.2100L1-4B350×4A162661029008.1114160M1-2B37.51251014504.07.5132M-4B370×2223664145057.54132M-4B31321649703.54132M1-6B370×4223361014509.5154160L-4B313216109706.511160L-6B3●性能表(3GR70×3)泵型号流量压力P转速n转/分功率P(千瓦)允许吸上真空高度(米)电动机型号米3/时升/分轴功率电动机功率3G3GR(75cst)70×32236510145013.8154Y160L-4B3223651616.718.5Y180M-4B322365)