HS115钴基铸棒 HS115钴基焊丝 耐高温堆焊焊丝

价格:420.00

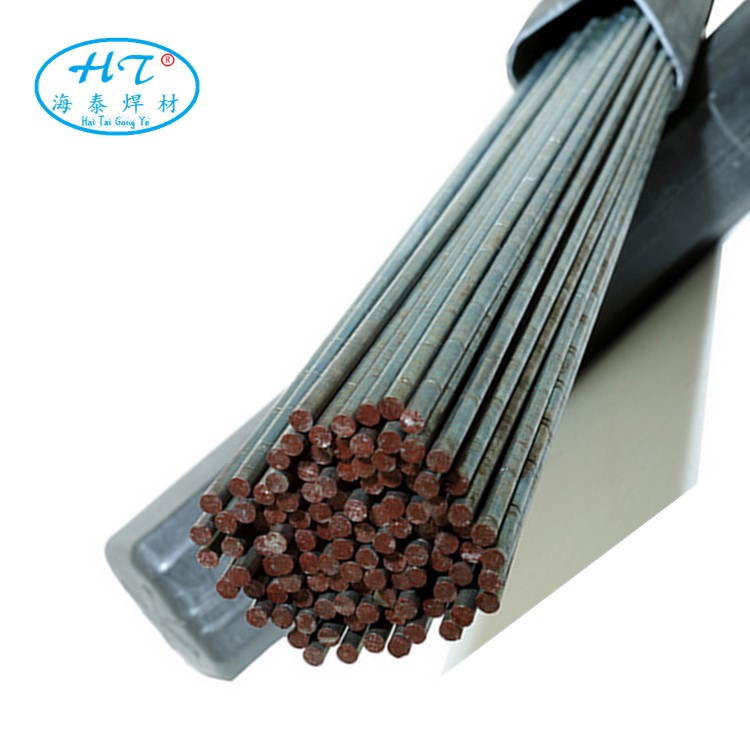

HS115钴基合金铸棒HS115钴基焊丝HS115焊丝用钼强化的低碳钴铬合金堆焊焊丝,室温下硬度较低,但冷作后硬度有所提高。堆焊层具有良好的男耐高温腐蚀,耐冲击能和良好的高温强度。用途:适用于各种液体阀门、阀座及水轮机叶片和铸模、挤压模的堆焊。焊丝具有的优良韧性和综合力学性能更能适用于各种热模具的堆焊。熔敷金属化学成分/%C1.5-3.5Cr25-29Mo5.0-6.0Ni1.75-3.25Co余量堆焊层硬度:HR***5-50许可证:XK06-009-00060注意事项:1、焊条焊前须经150℃左右烘焙1小时。2、宜采用小电流、短弧堆焊,以避免增加母材的熔深,降低堆焊合金的性能。3、根据母材的种类和工件大小,可选择350-500℃的预热温度和350℃的层间温度进行堆焊。4、根据工况条件一般选择600-750℃,保温1-2小时后随炉缓冷,或将工件置于干燥和预热的沙缸或草灰中缓冷。钴基合金铸棒钴基焊丝直径2.8-8.0mm的钴基系列合金,产品成分均匀,无偏析,杂质含量少,表面光洁,直径公差小,长度可自由选择,适用于氧***焊和钨极***弧焊工艺。斯米克钴基焊丝钴基铸棒铸棒CastRod硬度HDC化学成分(重量%)NominalChemicalComposition(wt%)应用(Application)CCrSiWFeMoNiCoMnHS11138-461.2029.001.204.503.001.003.00Ba11.00发动机气门,高温高压阀门,渦轮机叶片Enginevalve,hightemperature&pressurevalvesandturbinebaldeHS11244-501.4529.002.008.503.001.003.00Ba11.00高温高压阀门,锯齿,螺旋推杆等hightemperature&pressurevalves,sawteeth,screwflights,etcHS11350-602.5029.501.2012.503.001.003.00Ba11.00阀座,轴承,刀口等Valveseatinserts,bearing,cutteredge,etcHS11420-420.2527.001.000.152.005.502.50Ba11.00渦轮机叶片,各种液体阀,阀座,热冲模等turbinebalde,fluidvalve,valveseat,brasscastingdieHS115≥543.2026.001.0014.005.001.003.00Ba11.00石油钻具Petroleumdrillbit司太立钴基合金铸棒铸棒硬度化学成分(重量%)典型用途CCrSiWFeMoNiCoMnStellite1532.5029.501.2012.503.001.003.00Bal1.00阀座、轴承、刀口等Stellite3542.4031.001.0012.503.003.00Bal1.00针阀座、阀座、轧钢导向辊Stellite4480.9032.001.0013.501.000.500.50Bal0.50热压模、热挤压模、干电池工业Stellite6431.2029.001.204.503.001.003.00Bal1.00发动机气门、高温高压阀门、涡轮机叶片Stellite12471.4529.002.008.503.001.003.00Bal1.00高温高压阀门、锯齿、螺旋推杆等Stellite20542.4532.501.0017.003.001.003.00Bal0.50轴承套筒、耐磨板Stellite21200.2527.001.000.152.005.502.50Bal1.00涡轮机叶片、各种液体阀、阀座、热冲模等Stellite31330.5025.501.007.502.001.0010.50Bal1.00燃气涡轮叶片Stellite190583.2026.001.0014.005.001.003.00Bal1.00石油钻具Stellite706421.2030.001.202.005.002.00Bal1.00发动机气门、高温高压阀门Stellite712502.0029.002.002.008.502.00Bal2.00高温高压阀门、螺旋推杆Tribaloy400530.088.502.601.5028.501.50Bal用于高温强腐介质中的闸阀、挤塑器Tribaloy800550.0818.003.401.5028.501.50Bal用于高温强腐介质中的闸阀、挤塑器StelliteF401.7525.501.101.150.6022.50Bal0.30内燃机进排气阀产品图片:)