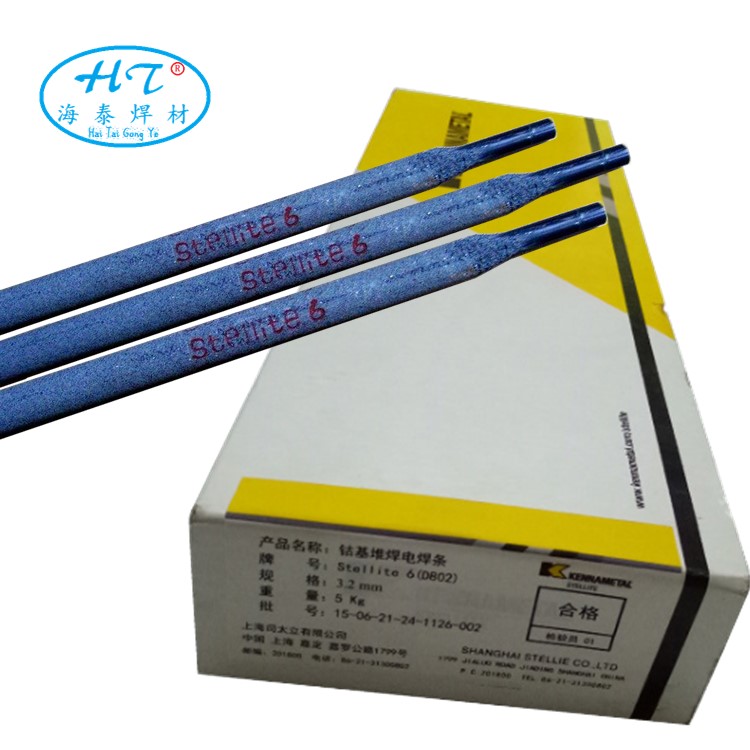

D832钴基堆焊焊条 耐高温耐磨焊条

价格:360.00

D832钴基堆焊焊条耐高温耐磨焊条型号:EDCoCr-C-03D832钴基堆焊焊条标准:AWSA5.13AMS5385用途:用于各种流体阀门、阀座及汽轮机叶片、叶轮的堆焊。其优良的韧性和机械性能适用于各种热冲模具的堆焊。堆焊硬度:HRC≥23注意事项:1、焊条焊前须经150℃左右烘焙1小时。2、宜采用小电流、短弧堆焊,以避免增加母材的熔深,降低堆焊合金的性能。3、根据母材的种类和工件大小,可选择350-500℃的预热温度和350℃的层间温度进行堆焊。4、根据工况条件一般选择600-750℃,保温1-2小时后随炉缓冷,或将工件置于干燥和预热的沙缸或草灰中缓冷。电焊条Electrode硬度HDC化学成分(重量%)NominalChemicalComposition(wt%)应用(Application)CCrSiWFeMoNiCoMnD80238-451.0029.001.004.505.000.503.00Ba11.00发动机气门,高温高压阀门,渦轮机叶片Enginevalve,hightemperature&pressurevalvesandturbinebaldeD81243-501.3529.001.009.005.000.503.00Ba11.00高温高压阀门,锯齿,螺旋推杆等hightemperature&pressurevalves,sawteeth,screwflights,etcD82246-552.2029.002.0014.005.000.503.00Ba11.00阀座,轴承,刀口等Valveseatinserts,bearing,cutteredge,etcD83220-400.3028.001.002.505.502.50Ba12.00渦轮机叶片,各种液体阀,阀座,热冲模等turbinebalde,fluidvalve,valveseat,brasscastingdie)